Wax Melt Warmer - Manon

Wax Melt Warmer - Manon

The Manon wax melt warmer — made exclusively for Rosie & B, and available in three gorgeous finishes.

Good to know: Save £5 when you also add any pack of Wax Melts to your basket.

Discount applied automatically at checkout.

Couldn't load pickup availability

About This Product

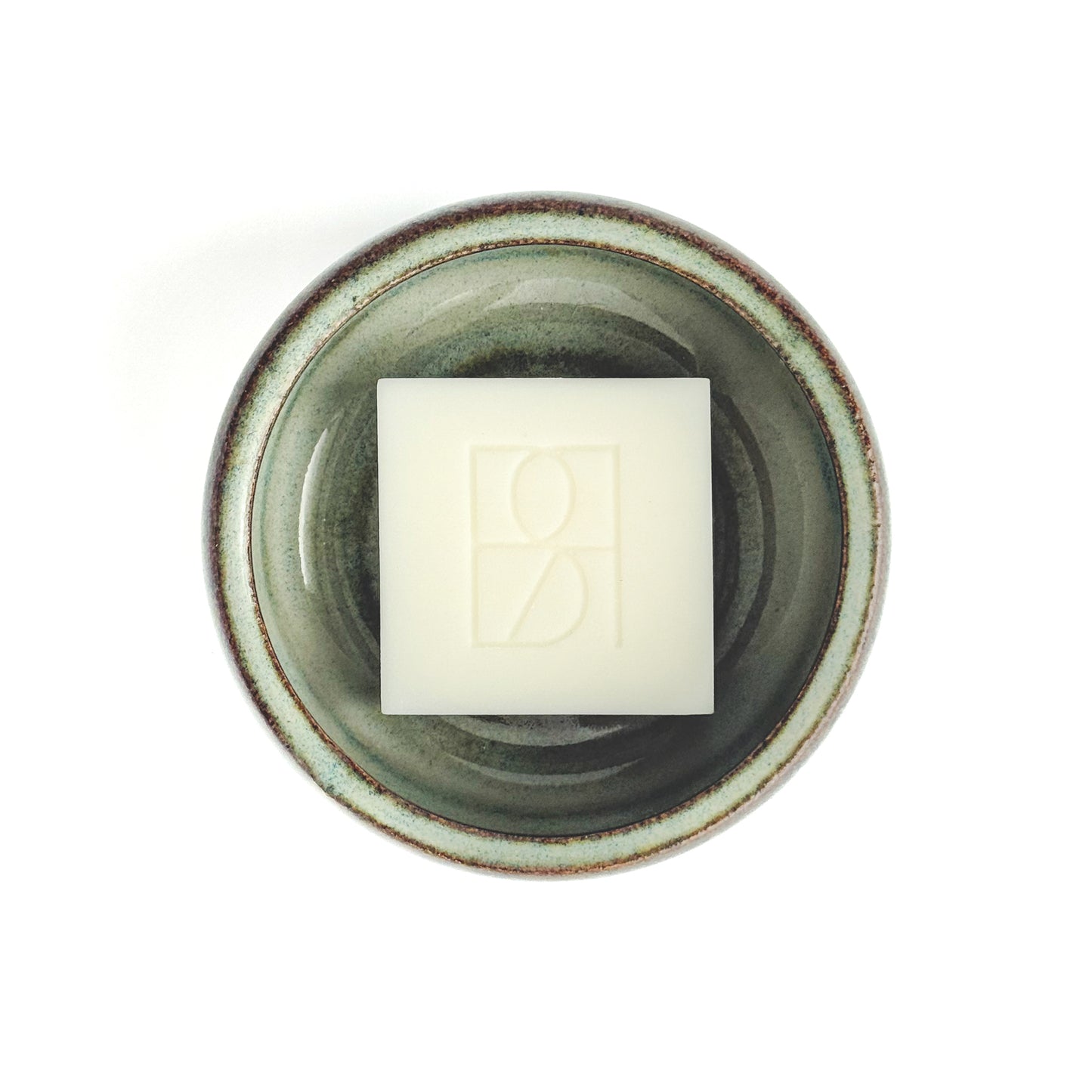

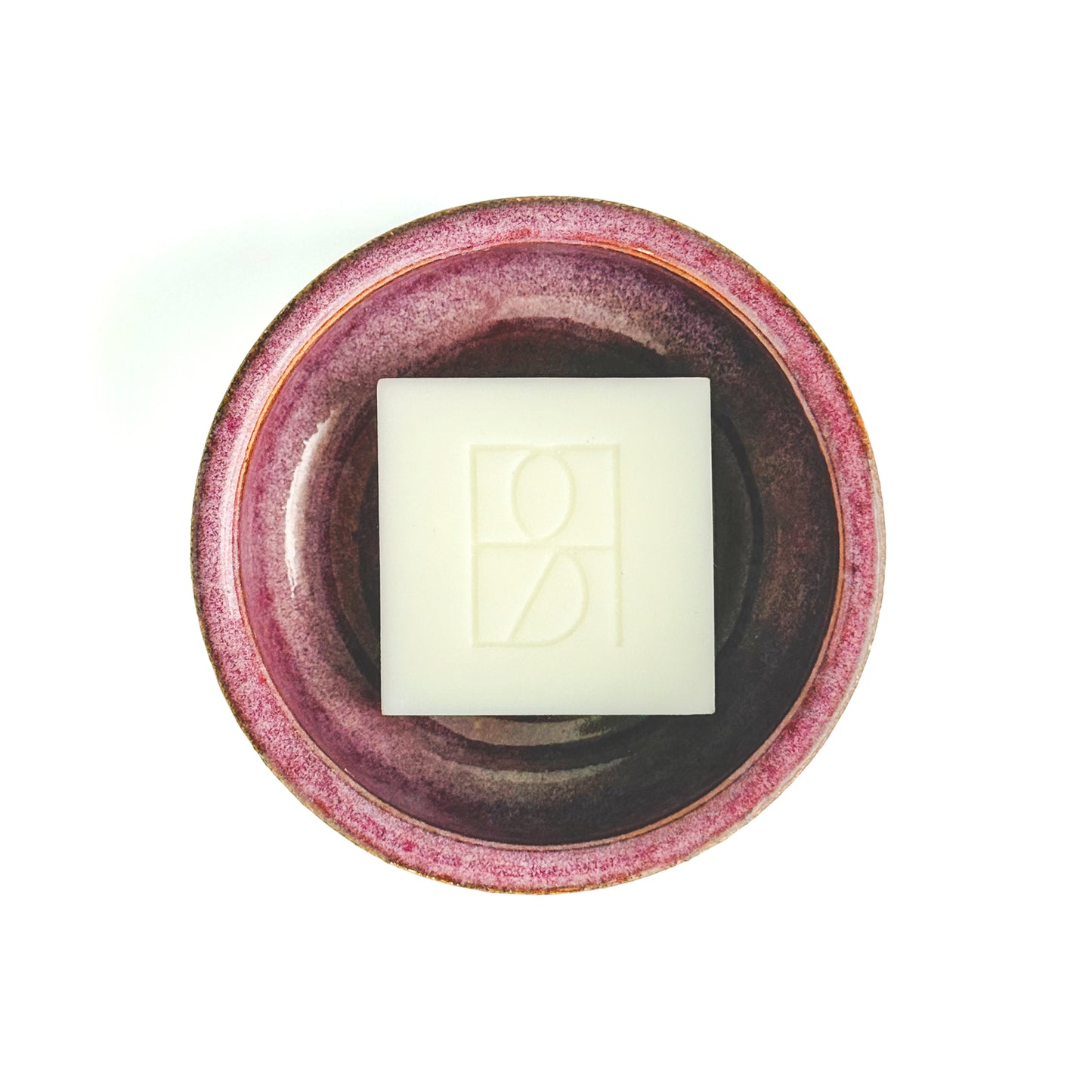

The Manon wax melt warmer is the result of a collaboration between Rosie & B and Janice Heyes of EpsomPots. Each piece is hand-thrown, hand-glazed, and designed to deliver beautiful fragrance performance. Available in three shades — Almond Sepia, Forest Teal, and Orchard Plum — the Manon brings a quiet elegance to any space.

The Manon is made from wheel-thrown stoneware and finished with a layered glaze, applied by brush over bare clay. The form has been carefully shaped to suit the science behind Rosie & B wax melts — with a focus on airflow, temperature control and scent throw. This balance of form and function is the result of close collaboration between the two makers.

Due to their handmade nature, our Manon warmers feature unique characteristics, meaning variations in appearance are to be expected. Please note that the product images shown are for reference only, as your warmer will have its own individual beauty.

Simply place a 1.5cm, 4 hour unscented tea light inside the warmer and add a Rosie & B wax melt to the dish. Light the tea light, then indulge in the fragrance and enjoy the soft glow of the flame.

Dimensions: Approximately 13cm (H), 7.5cm (Diameter)

Meet the potter

Janice Heyes, of EpsomPots, is a ceramic artist based in Epsom, Surrey, who specialises in creating pieces of art for everyday use, combining bare clay with thick, expressive glazes.

With a focus on sustainability, she uses a low-impact, single-firing process in her studio — a pre-industrial technique that reduces energy use and supports more environmentally conscious making.

Our collaboration brings together the crafts of fragrance and pottery. In Janice’s words:

“We’ve exchanged the science and beauty of both our crafts and I have learned so much in the process. Refining the oxygen flow and the burn temperature using varying thicknesses of clay and positions of the cut-out holes has involved a new level of precision in my making — for which I am truly grateful.”